Recent Posts

-

Meet TYM at K 2025 -The World’ s No.1 Trade Fair for Plastics and Rubber

Welcome to the World’s No.1 Trade Fair for Plastics and Rubber -K 2025, taking place from October 8–15, 2025 at Messe Düsseldorf, Germany. As a professional LSR injection molding machine, mold, and robot solution provider, TYM Technology Co., Ltd. is proud to present our latest innovations at Booth 16E77.

09/23/2025

-

TYM LSR Molding Solutions at Plast Eurasia Istanbul 2025

Meet TYM at Plast Eurasia 2025 to explore LSR injection molding machines, silicone and plastic molding systems, and turnkey LSR solutions. Booth: hall 805.

12/02/2025

-

LSR Overmold Technology | Liquid Silicone Rubber Injection Molding

Liquid Silicone Rubber (LSR) overmolding has become a core manufacturing technology for producing high-precision, food-grade silicone components used in baby products, kitchenware, and consumer goods.

11/25/2025

-

Efficient Production of Silicone Phone Covers|Vertical Molding Machines

Produce premium silicone phone covers efficiently with TYM LSR vertical injection molding machines. Achieve perfect overmolding, high precision, and full automation for durable, skin-friendly silicone cases.

11/13/2025

-

Efficient LSR Half Mask Respirator Production with TYM LSR Molding Machines

What Is an LSR Half Mask Respirator? This type of respirator is made through a combination of plastic injection and LSR overmolding. First, the plastic part of the mask is molded. Then it is placed into a silicone mold for a second injection on an LSR molding machine. During this process, the liquid silicone bonds tightly with the plastic surface, forming one complete piece without any need for glue or manual assembly. This makes the mask more stable, cleaner, and easier to produce in volume.

10/09/2025

-

Liquid Silicone Half Mask Respirator Production Machine

Liquid silicone half mask respirator mold can be customized with 2 to 4 cavities and adopts a cold runner system to minimize material waste while achieving high precision molding machine.

08/14/2025

-

Silicone Catheter Manufacturing Machine LSR Molding and Extrusion

TYM provides LSR molding and extrusion solutions to manufacture silicone catheters efficiently, with modular molds and global medical-grade support.

06/25/2025

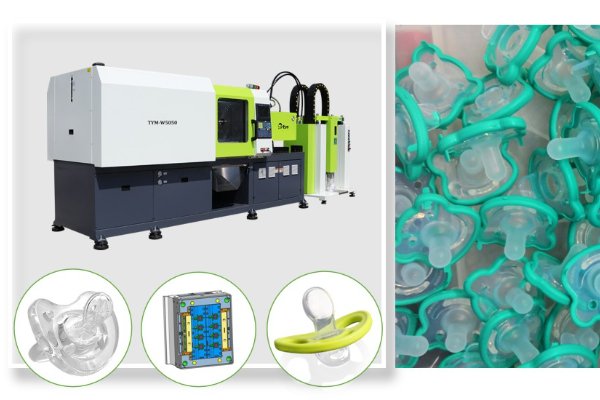

Why LSR injection molding is widely used ?

Due to ue the thermosetting nature of the LSR material ,LSR injection molding has been widely used in various kinds of industry production , such as: medical, baby bottle and nipple,automotive, aerospace, electrical, sex toys, and other industrial applications. Among the most tested biomaterials, silicones are increasingly desired based on their unique combination of biocompatibility and performance properties,that made silicone rubber become the most popular option when making parts.

Now let's learn what it gets:

*Chemically inert, tasteless, odorless, and stainless;

*Biocompatible and short/long-term implantable;

*Bacterial resistant and easy to clean and sterilize;

*Temperature flexible – 180°F to 600°F;

*Chemical resistant;

*Fatigue and compression set resistant;

*Lubricious for less invasive biological applications;

*Elongatable: 100 – 900%.

As Liquid Silicone Rubber (LSR) material it's own outstanding properties, it meet the multiple requirements in various kinds of the high-end products, especially in baby product ,medical product and sex toys industry. Thought LSR has good performance , injection molding of liquid silicone rubber requires special treatment, such as uniform distributive mixing. In addition, the material must be maintained at a constant temperature up until it is pushed into the heated cavity and vulcanized. For more informations about the LSR injection molding, you can follow us at www.tymsilicone.com .

As a leading company in manufacturing high precision parts and components, TYM team are exclusively focused and specialized in the production of LSR components, just feel free to contact us .