Recent Posts

-

Meet TYM at K 2025 -The World’ s No.1 Trade Fair for Plastics and Rubber

Welcome to the World’s No.1 Trade Fair for Plastics and Rubber -K 2025, taking place from October 8–15, 2025 at Messe Düsseldorf, Germany. As a professional LSR injection molding machine, mold, and robot solution provider, TYM Technology Co., Ltd. is proud to present our latest innovations at Booth 16E77.

09/23/2025

-

TYM LSR Molding Solutions at Plast Eurasia Istanbul 2025

Meet TYM at Plast Eurasia 2025 to explore LSR injection molding machines, silicone and plastic molding systems, and turnkey LSR solutions. Booth: hall 805.

12/02/2025

-

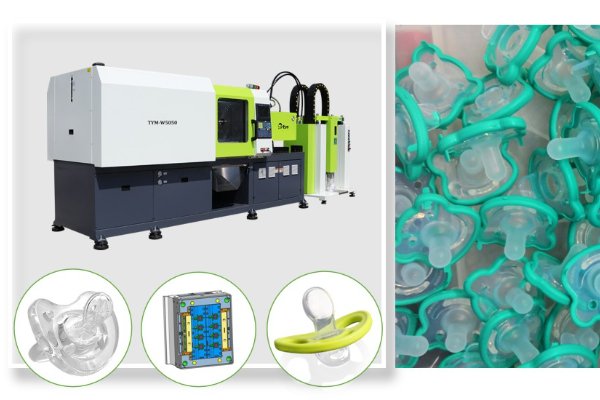

LSR Overmold Technology | Liquid Silicone Rubber Injection Molding

Liquid Silicone Rubber (LSR) overmolding has become a core manufacturing technology for producing high-precision, food-grade silicone components used in baby products, kitchenware, and consumer goods.

11/25/2025

-

Efficient Production of Silicone Phone Covers|Vertical Molding Machines

Produce premium silicone phone covers efficiently with TYM LSR vertical injection molding machines. Achieve perfect overmolding, high precision, and full automation for durable, skin-friendly silicone cases.

11/13/2025

-

Efficient LSR Half Mask Respirator Production with TYM LSR Molding Machines

What Is an LSR Half Mask Respirator? This type of respirator is made through a combination of plastic injection and LSR overmolding. First, the plastic part of the mask is molded. Then it is placed into a silicone mold for a second injection on an LSR molding machine. During this process, the liquid silicone bonds tightly with the plastic surface, forming one complete piece without any need for glue or manual assembly. This makes the mask more stable, cleaner, and easier to produce in volume.

10/09/2025

-

Liquid Silicone Half Mask Respirator Production Machine

Liquid silicone half mask respirator mold can be customized with 2 to 4 cavities and adopts a cold runner system to minimize material waste while achieving high precision molding machine.

08/14/2025

-

Silicone Catheter Manufacturing Machine LSR Molding and Extrusion

TYM provides LSR molding and extrusion solutions to manufacture silicone catheters efficiently, with modular molds and global medical-grade support.

06/25/2025

Liquid Silicone Rubber Injection Molding---History Introduction

Liquid Silicone Rubber Injection Molding (LSR injection molding) has been widely used in many markets due to its ability to produce intricate elastomeric components with relatively short cycle times.

The automotive industry uses silicone's high degradation temperatures for engine sealing and medical components markets rely on its biological inertness. Liquid Silicone Rubber (LSR) can be processed using slightly modified thermoplastic molding equipment, making them easy to integrate into existing business structures and facilities. Also, an increase in use has driven down the raw material cost of LSRs as to make them more competitive with historically less expensive thermoplastic elastomers, thus extending their use into new markets in recent years. An increase in specialized auxiliary equipment such as demolding devices will further facilitate LSR push to the mainstream of polymer manufacturing.

Among the whole silicone material, Liquid Silicone Rubber (LSR) has a relatively short history.

Developed during the late 1970s, LSR two component systems have quickly increased in popularity over the past 30 years due to their

advantages over Gum Silicone Rubbers. Not only are faster cycle times and flashless molding possible, but all secondary equipment is contained near the molding press and there is no need to mill or process the material in any way prior to use. Also , LSR is popular due to its ability to compete with typical thermoplastic elastomers which allowing for minimal initial capital investment.

In next part, we will try to write something about the material and the process about the liquid silicone rubber molding, kindly contact for more details .