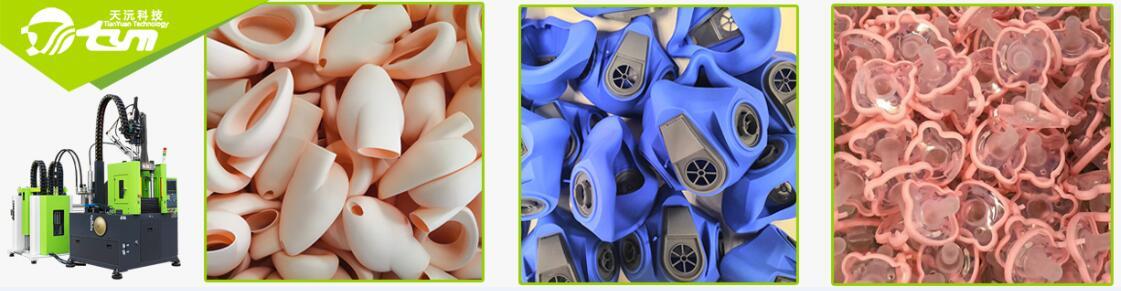

Liquid silicone rubber injection molding machine for mask, protective mask

- Product Detail

| Clamping Unit | |

|---|---|

| Clamping Force | 130T |

| Opening Stroke | 250-550 mm |

| Tie-Bars Space | 500*580 mm |

| Ejection Force | 7.8 T |

| Ejection Stroke | 165g |

| Injection Unit | |

| Shot Volume | 300g |

| Injection Rate | 30 g/s |

| Injection Pressure | 19.6 T |

| Others | |

| Pump Pressure | 21 Mpa |

| Motor Power | 12.1KW |

| Heater Power | 9 KW |

| Mould Orientation Ring Diameter | Φ 100 mm |

| Machine Weight | 5.5T |

| Machine Dimension | 1.7*1.6*3.4 m |

TYM manufacture Liquid silicone rubber injection molding machine for mask, protective mask, gas mask

TYM professionally design and produce the LSR (liquid silicone rubber) injection molding machine, LSR injection mold and ODM silicone products with more than 16 years. Our LSR injection machine are wide used in the silicone medical parts, silicone baby products, silicone labor protection products, silicone diving products, silicone kitchen ware, silicone electronic accessory, silicone automobile accessory etc. For the LSR injection molding process, we can make the silicone parts, silicone overmolded with the PC/PA/PPSU/Metal/Glass/ Graphite plate parts, and two-color silicone parts.

Closing the mould downward, two kinds of models can be chose – single sliding board and double sliding board. For double sliding board LSR machine, one upper moldboard and two lower moldboards are installed, which improves the production efficiency. The sliding out structure on the machine makes the production more conveniently and more safely. Also the vertical mould opening and closing is more suitable for producing the overmold (inmold) LSR parts which has inserts.

The main feature of the vertical LSR molding machine:

Advanced sliding rail structure, which can reduce the oil pollution and make the machine works faster and steadier.

Active pin valve-pattern nozzle sealing system, which can guarantee the injection more accurately.

Meet the requirements on multi-station production

High-performance servo motor system is installed, which can guarantee the machine work more accurately and more energy-savingly.

The vertical LSR machine for the applicable scope:

Liquid silicone products, which can with the insert, as like the plastic part, steel part etc. As sample: silicone diving mask, electric silicone drum Stick, silicone handle, silicone vibrators etc..

Liquid silicone medical part, as like the capsule, laryngeal mask capsule, oxygen mask, protective mast, catheter, balloon, medical belt etc.

Silicone high-voltage cable accessories,

Electronics and industrial product, such as the watchband, mobile phone case, valve, O-ring, sealing part, auto parts more.

Sex products, such as the vibrating spear, sex toy coat, adult supplies etc.