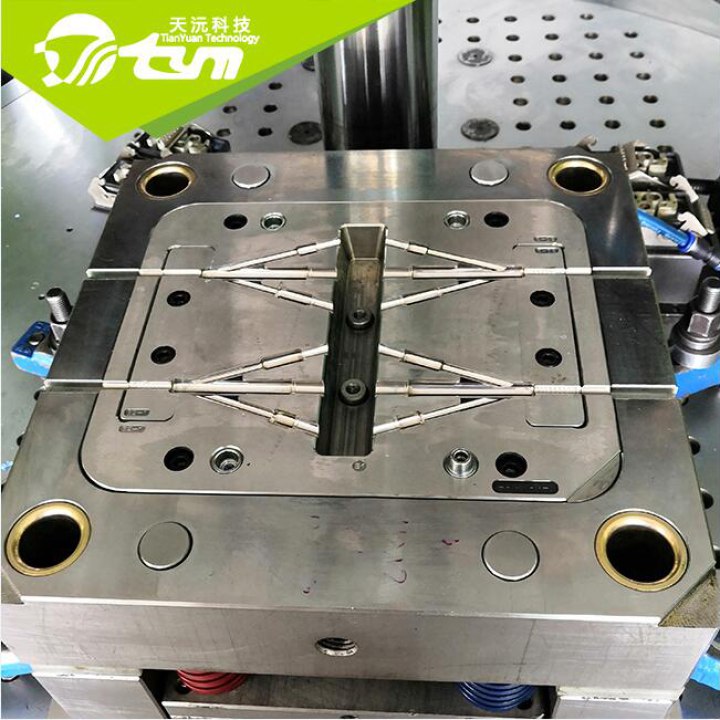

Silicone injection mold for medical catheter, stomach tube

- Product Detail

Silicone injection mold for medical catheter, stomach tube

TYM Production Ability

Guangzhou Tianyuan Silicone Machine Technology Co.,Ltd.(Hereinafter referred to as TYM-Tech) was established in 2002. During past 17 years, TYM-Tech has been forcusing on R&D, manufacturing and technical services of precision LSR injection tool(mold). The factory convers an area of 5,000 square meters and it located in Shiji Town, Panyu District, Guangzhou City. So far factory has sveral advanced high-precision tool processing equipment and multiple inspection equipments such as secondary element, CMM, material hardness tester, inlcuding 7 pieces of CNC including 3 pieces of fine carving machines), 4 pieces of sparking machines(2 pieces of Taiwan automatic mirror sparking machines), 4 pieces of milling machines(3 pieces of Jiande precision grinding machines). TYM-Tech has a professional tool design and development team and many experienced tool processing masters.

LSR Mold Applicable Industry

TYM-Tech has more than 2000 sucessful cases for LSR injection tool(mold) designing and manufacturing. They have been widely applied in the baby care industry, medical supplies industry, electrionic parts industry, new energy vehicle industry, safety protection industry, Hutch defends supplies industry, auto parts industry and other fields.

TYM Production Qualification Certification

TYM-Tech has 17 years of experience in tool(mold) designing and manufacturing. It has obtained ISO9001 international quality management system certification, environmental assessment certification. TYM-Tech has established a excellent quality management system and 6S management. One-to-One pre-sales and after sales services have satisified customers' requirements on product quality and delivery to win customers' praise and trust. The LSR injection molding machine and tool(mold) have been exported to more than 40 countries including USA, Germany, Spain, Brazil, Mexico, Russia, Poland, England, Turkey, Italy, Saudi Arabia, Malysia, Thailand, India, South Africa, Algeria, Egypt and so on.

LSR injection molding industry application

Maternal and baby industry: The safety and forming process of liquid silicone materials are non-pollution, and have been widely used in the production of silicone products such as nipples, pacifiers, teether , bottles, spoons, suckers, brushes and so on in the maternal and baby industry.

Medical industry: The good biological characteristics and high-quality forming technology of liquid silicone materials have been widely used in the silicone accessories such as catheter & the joint, gastric tube, laryngeal mask, mask, dental bracket, negative pressure ball, incision protective cover, balloon and so on in the medical industrial.

Electronics industry: The waterproof, elastic and high precision forming process of liquid silicone material has been widely used in the silicone parts such as joint waterproof seals, horn diaphragm, mobile phone case, watch belt, button, earphone and so on in the electronics industry.

Automobile Parts Industry: The high permeability and high efficiency production process of liquid silicone material has been widely used in the silicone accessories such as LED perspective mirror,spark plug protector, wire harness seal ,sealing strips in automobile parts industry.

Labor Protection Industry: The soft touch, odorless and stable forming process of liquid silicone material has been widely used in the protective masks, gas masks, anti-dust and haze masks, noise-proof earplugs, protective mirror frames and other silicone parts in the labor protection industry.

Kitchen and sanitary industry: The production of liquid silicone material with high and low temperature resistance, non-toxicity and high qualified rate has been widely used in the production of cake mold, chocolate mold, stir-frying shovel, sprinkler, seal washer with pot cover and other silicone products in kitchen and sanitary industry.