Recent Posts

-

Welcome to visit TYM’s booth in CHINAPLAS 2024

The 36th China International Plastics and Rubber Industry Exhibition will be held on April 23-26,2024

04/01/2024

-

Guangdong International Robot & Intelligent Manufacturing Expo

And display 3 newest LSR equipment and the manufacture technique of sophisticated LSR mould working in the equipment: 3 worktable rotate double-color LSR injection molding machine, double-material injection molding machine and double sliding plate vertical LSR injection molding machine.

12/08/2015

-

Liquid Silicone Half Mask Respirator Production Machine

Liquid silicone half mask respirator mold can be customized with 2 to 4 cavities and adopts a cold runner system to minimize material waste while achieving high precision molding machine.

08/14/2025

-

Silicone Catheter Manufacturing Machine LSR Molding and Extrusion

TYM provides LSR molding and extrusion solutions to manufacture silicone catheters efficiently, with modular molds and global medical-grade support.

06/25/2025

-

Liquid silicone injection molding machine need auxiliary machine?

With the development of liquid silica gel industry in recent years, the demand for liquid silica gel equipment is becoming more and more obvious. So what kind of structure is liquid silicone injection molding machine, it needs auxiliary equipment? And a variety of other molding equipment similar reasoning, the same is the need for auxiliary equipment.

05/15/2025

-

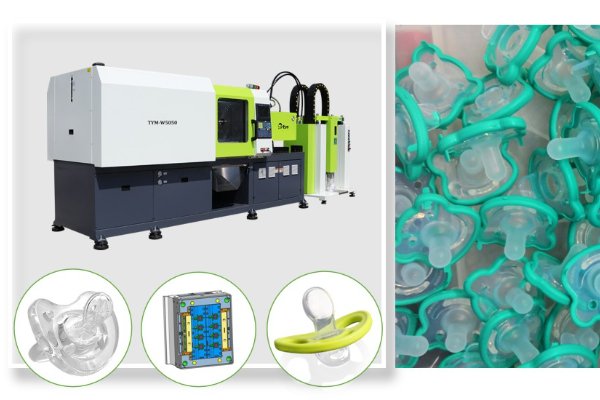

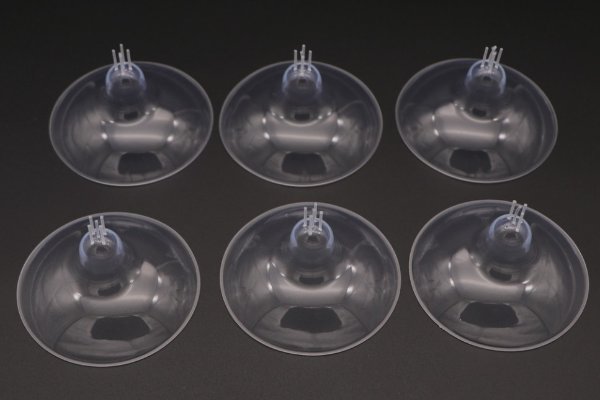

Plastic or LSR Injection Molding Machine | Breast Pump LSR Machine Guide

Discover how LSR injection molding machines enhance breast pump production. Learn the difference from plastic machines and why breast pump LSR machines need.

04/25/2025

-

Double Color Injection Machines: Multi-Color LSR Molding for Applications

Discover how double color injection machines revolutionize multi-color liquid silicone rubber (LSR) molding. Work with leading LSR injection molding machine manufacturers like TYM to boost your B2B production capabilities.

04/09/2025

Applications of LSR Injection Molding in Medical Device Manufacturing

The use of Liquid Silicone Rubber (LSR) injection molding in medical device manufacturing has become increasingly prevalent, thanks to the material's unique properties and benefits. LSR offers a combination of flexibility, durability, and biocompatibility that makes it ideal for producing a wide range of medical components and devices.

One of the primary applications of LSR injection molding in the medical field is the production of silicone implants and prosthetics. LSR's biocompatibility and ability to mimic the properties of human tissue make it an excellent choice for manufacturing implants such as breast implants, cochlear implants, and soft tissue fillers. Additionally, LSR's durability ensures long-term performance and patient safety in implantable medical devices.

LSR injection molding is also widely used in the production of medical tubing, catheters, and seals due to its flexibility and resistance to fluids and chemicals. Whether it's silicone tubing for peristaltic pumps or specialized catheters for minimally invasive procedures, LSR offers superior performance and reliability in medical applications.

Another key advantage of LSR injection molding in medical device manufacturing is its ability to produce complex geometries and intricate designs with high precision. From microfluidic devices to intricate surgical instruments, LSR machines can create components with tight tolerances and minimal flash, ensuring consistent quality and performance in medical devices.

In conclusion, LSR injection molding plays a crucial role in the manufacturing of medical devices, offering unique advantages such as biocompatibility, durability, and precision molding capabilities. As the demand for innovative medical solutions continues to grow, LSR injection molding machines will remain indispensable tools for producing high-quality medical components and devices.