Recent Posts

-

Welcome to visit TYM’s booth in CHINAPLAS 2024

The 36th China International Plastics and Rubber Industry Exhibition will be held on April 23-26,2024

04/01/2024

-

Guangdong International Robot & Intelligent Manufacturing Expo

And display 3 newest LSR equipment and the manufacture technique of sophisticated LSR mould working in the equipment: 3 worktable rotate double-color LSR injection molding machine, double-material injection molding machine and double sliding plate vertical LSR injection molding machine.

12/08/2015

-

Plastic or LSR Injection Molding Machine | Breast Pump LSR Machine Guide

Discover how LSR injection molding machines enhance breast pump production. Learn the difference from plastic machines and why breast pump LSR machines need.

04/25/2025

-

Double Color Injection Machines: Multi-Color LSR Molding for Applications

Discover how double color injection machines revolutionize multi-color liquid silicone rubber (LSR) molding. Work with leading LSR injection molding machine manufacturers like TYM to boost your B2B production capabilities.

04/09/2025

-

Visit TYM at CHINAPLAS 2025-Explore Cutting-Edge LSR Injection Molding Machine

Join TYM at CHINAPLAS 2025 from April 15-18 in Shenzhen! Visit Booth 8A21 to explore our advanced LSR injection molding machines and custom molding solutions.

04/01/2025

-

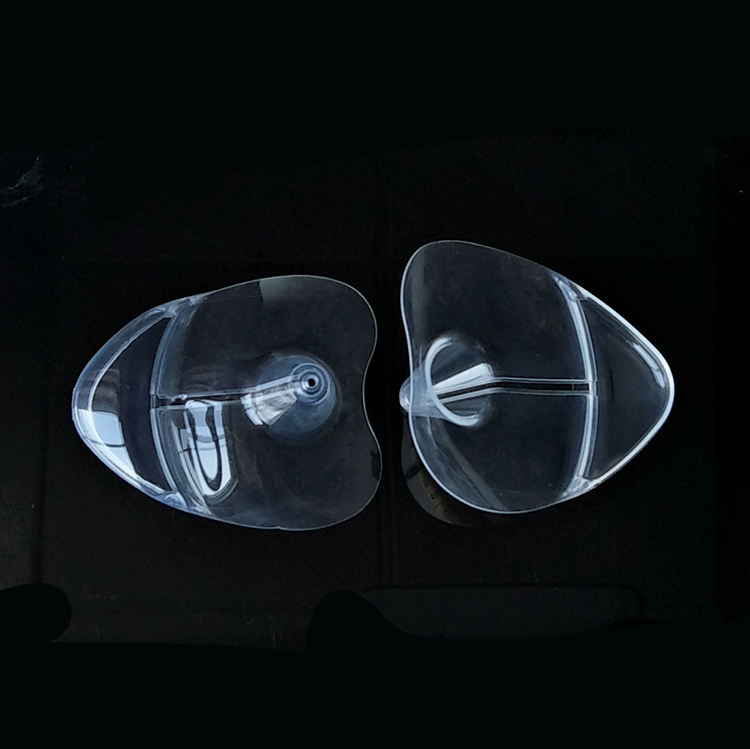

Optimizing Production with Horizontal LSR Injection Molding Machines|Silicone Nipple Mold

Our custom silicone nipple mold solution is designed for high-efficiency, high-quality production using a 130T Horizontal LSR injection molding machine. This setup ensures seamless automation, making it ideal for clients seeking a fully automated production process. The silicone nipple mold features an 8-cavity cold runner system, optimized for liquid silicone rubber (LSR) material, which guarantees precision and consistency in every product. With this system, we achieve a cycle time of appr

03/21/2025

-

LSR Machines: Tips for Accuracy & Mold Setup with LSR Injection Molding

Silicone injection moulding machine are very important for making liquid silicone rubber (LSR) products. These Isr injection molding machine used in many industries, such as medicine, cars and electronics, because they can produce very precise, strong, and flexible parts. But it is very important to get the sizes right and ensure that the moulds are properly placed. This makes the production process is faster and more efficient.

03/05/2025

-

Enhancing Product Design with LSR Injection Molding Technology

Discover how Liquid Silicone Rubber (LSR) injection molding technology enables designers to push the boundaries of product design. Learn how the flexibility and versatility of LSR molds empower manufacturers to create innovative and functional products.

04/05/2024

-

Understanding the Advantages of LSR Injection Molding Machines

Learn about the advantages of using Liquid Silicone Rubber (LSR) injection molding machines in various industries. Discover why LSR machines are preferred for their precision, durability, and efficiency.

03/28/2024

-

Applications of LSR Injection Molding in Medical Device Manufacturing

Discover how Liquid Silicone Rubber (LSR) injection molding machines are revolutionizing the production of medical devices. Learn about the unique properties of LSR that make it ideal for manufacturing critical components used in healthcare applications.

01/22/2024

Plastic or LSR Injection Molding Machine | Breast Pump LSR Machine Guide

Introduction

This blog looks at the equipment used to make breast pumps. It compares plastic injection machine and LSR injection molding machine.

If you're a breast pump brand, OEM, or a factory looking to upgrade your current production line, this guide will explain how breast pump LSR machine can help your business and improve product quality.

LSR Injection Molding Machine (Breast Pump LSR Machine)

Liquid Silicone Rubber injection moulding machines are specially designed to process two-component, low-viscosity LSR materials that stick to themselves, can resist heat, are hypoallergenic and FDA compliant. These are perfect for breast pump parts that touch skin or milk.

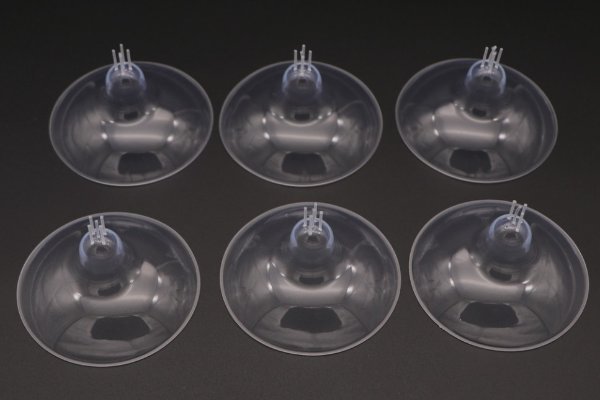

Typical LSR Breast Pump Components

Silicone flanges

Flexible membranes

Valves and sealing rings

Nipple covers and breast shields

Plastic Injection Machine VS LSR Injection Molding Machine

What are the LSR injection molding machine for breast pump LSR machine? On the silicone breast pump for maternal and infant industry, except for the electronic parts, the rest of the parts, are composed of plastic parts and LSR injection molding machine, that is to say breast pump LSR machine, mainly contains plastic injection molding machine and LSR injection machine.

Are you familiar with the logic behind the fact that plastic injection moulding and LSR injection machines are different?

1. Plastic Injection Molding Machine

Plastic injection molding machine operates on the principle of thermoplastic or thermosetting plastic using injection molding molds, and then produces various shapes of plastic products.

Commonly known plastic materials, such as PP, PC, PPSU, etc., need to be produced by plastic injection molding machine. To do this, we need to place plastic granules inside a funnel and melt them, then inject them into a plastic mold where they are cooled and molded. This process is a physical change, and the plastic material can be recycled.

This blog examines the equipment used to manufacture breast pumps. It compares plastic injection machines and liquid silicone rubber (LSR) injection molding machines. It also explains why LSR machines require additional equipment to operate at their best.

If you are a breast pump brand, original equipment manufacturer (OEM), or a factory looking to upgrade your current production line, this guide will explain how breast pump LSR machines can benefit your business and enhance product quality.

2.LSR Injection Machine

The working principle of LSR injection machine

LSR injection molding machine: the liquid silicone raw material contains A and B two components, through the silicone machine on the quantitative pump to control the ratio of the two 1:1, and then through the dynamic and static mixer to give the material is fully mixed (color paste with a third agent to add to the mixer with the full mix of A/B) through the gun barrel injection into the mold, high temperature vulcanization molding. ) The mixed material is injected into the mold through the barrel and vulcanized at high temperature.

This is a chemical reaction, LSR cannot be recycled.

Generally Speaking

The two machines are suitable for different customers' production requirements. Plastic injection moulding machines operate by transforming the plastic material into a new product. This means that the plastic can be recycled.

The LSR injection moulding machine functions by utilizing a chemical reaction. This means that liquid silicone cannot be recycled.

Welcome! Here you can learn more about how our LSR injection machine can assist your business, and the benefits it can provide to customers at the B-end.

E-mail [email protected],[email protected], WhatsApp +8618814115468.