Recent Posts

-

Meet TYM at K 2025 -The World’ s No.1 Trade Fair for Plastics and Rubber

Welcome to the World’s No.1 Trade Fair for Plastics and Rubber -K 2025, taking place from October 8–15, 2025 at Messe Düsseldorf, Germany. As a professional LSR injection molding machine, mold, and robot solution provider, TYM Technology Co., Ltd. is proud to present our latest innovations at Booth 16E77.

09/23/2025

-

TYM LSR Molding Solutions at Plast Eurasia Istanbul 2025

Meet TYM at Plast Eurasia 2025 to explore LSR injection molding machines, silicone and plastic molding systems, and turnkey LSR solutions. Booth: hall 805.

12/02/2025

-

LSR Overmold Technology | Liquid Silicone Rubber Injection Molding

Liquid Silicone Rubber (LSR) overmolding has become a core manufacturing technology for producing high-precision, food-grade silicone components used in baby products, kitchenware, and consumer goods.

11/25/2025

-

Efficient Production of Silicone Phone Covers|Vertical Molding Machines

Produce premium silicone phone covers efficiently with TYM LSR vertical injection molding machines. Achieve perfect overmolding, high precision, and full automation for durable, skin-friendly silicone cases.

11/13/2025

-

Efficient LSR Half Mask Respirator Production with TYM LSR Molding Machines

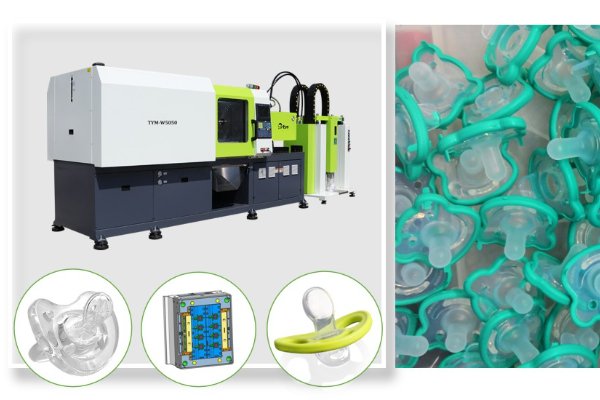

What Is an LSR Half Mask Respirator? This type of respirator is made through a combination of plastic injection and LSR overmolding. First, the plastic part of the mask is molded. Then it is placed into a silicone mold for a second injection on an LSR molding machine. During this process, the liquid silicone bonds tightly with the plastic surface, forming one complete piece without any need for glue or manual assembly. This makes the mask more stable, cleaner, and easier to produce in volume.

10/09/2025

-

Liquid Silicone Half Mask Respirator Production Machine

Liquid silicone half mask respirator mold can be customized with 2 to 4 cavities and adopts a cold runner system to minimize material waste while achieving high precision molding machine.

08/14/2025

The Environmental Benefits of LSR Injection Molding Machines

In an era where environmental sustainability is a top priority for manufacturers, Liquid Silicone Rubber (LSR) injection molding machines offer several advantages that align with green manufacturing principles. From reduced material waste to energy efficiency and recyclability, LSR injection molding contributes to sustainable practices in the manufacturing industry.

One of the primary environmental benefits of LSR injection molding is its material efficiency. Unlike traditional molding processes that generate significant scrap and excess material, LSR injection molding minimizes waste by precisely dispensing the required amount of silicone rubber for each mold. This results in lower material costs and less environmental impact associated with material disposal.

Furthermore, LSR injection molding machines are designed for energy efficiency, with advanced heating and cooling systems that optimize energy consumption during the molding process. By minimizing energy usage and maximizing process efficiency, LSR machines reduce carbon emissions and contribute to overall energy conservation in manufacturing facilities.

Another environmentally friendly aspect of LSR injection molding is the recyclability of silicone rubber materials. Unlike many plastics that degrade over time and release harmful chemicals into the environment, silicone rubber can be recycled and reused in various applications. This closed-loop recycling process helps reduce the demand for virgin materials and minimizes the environmental footprint of LSR manufacturing.

In conclusion, LSR injection molding machines offer significant environmental benefits that make them a sustainable choice for manufacturers seeking to minimize their ecological impact. From material efficiency and energy conservation to recyclability, LSR injection molding contributes to a more environmentally friendly approach to manufacturing.