Recent Posts

-

Welcome to visit TYM’s booth in CHINAPLAS 2024

The 36th China International Plastics and Rubber Industry Exhibition will be held on April 23-26,2024

04/01/2024

-

Guangdong International Robot & Intelligent Manufacturing Expo

And display 3 newest LSR equipment and the manufacture technique of sophisticated LSR mould working in the equipment: 3 worktable rotate double-color LSR injection molding machine, double-material injection molding machine and double sliding plate vertical LSR injection molding machine.

12/08/2015

-

Plastic or LSR Injection Molding Machine | Breast Pump LSR Machine Guide

Discover how LSR injection molding machines enhance breast pump production. Learn the difference from plastic machines and why breast pump LSR machines need.

04/25/2025

-

Double Color Injection Machines: Multi-Color LSR Molding for Applications

Discover how double color injection machines revolutionize multi-color liquid silicone rubber (LSR) molding. Work with leading LSR injection molding machine manufacturers like TYM to boost your B2B production capabilities.

04/09/2025

-

Visit TYM at CHINAPLAS 2025-Explore Cutting-Edge LSR Injection Molding Machine

Join TYM at CHINAPLAS 2025 from April 15-18 in Shenzhen! Visit Booth 8A21 to explore our advanced LSR injection molding machines and custom molding solutions.

04/01/2025

-

Optimizing Production with Horizontal LSR Injection Molding Machines|Silicone Nipple Mold

Our custom silicone nipple mold solution is designed for high-efficiency, high-quality production using a 130T Horizontal LSR injection molding machine. This setup ensures seamless automation, making it ideal for clients seeking a fully automated production process. The silicone nipple mold features an 8-cavity cold runner system, optimized for liquid silicone rubber (LSR) material, which guarantees precision and consistency in every product. With this system, we achieve a cycle time of appr

03/21/2025

-

LSR Machines: Tips for Accuracy & Mold Setup with LSR Injection Molding

Silicone injection moulding machine are very important for making liquid silicone rubber (LSR) products. These Isr injection molding machine used in many industries, such as medicine, cars and electronics, because they can produce very precise, strong, and flexible parts. But it is very important to get the sizes right and ensure that the moulds are properly placed. This makes the production process is faster and more efficient.

03/05/2025

-

Enhancing Product Design with LSR Injection Molding Technology

Discover how Liquid Silicone Rubber (LSR) injection molding technology enables designers to push the boundaries of product design. Learn how the flexibility and versatility of LSR molds empower manufacturers to create innovative and functional products.

04/05/2024

-

Understanding the Advantages of LSR Injection Molding Machines

Learn about the advantages of using Liquid Silicone Rubber (LSR) injection molding machines in various industries. Discover why LSR machines are preferred for their precision, durability, and efficiency.

03/28/2024

-

Applications of LSR Injection Molding in Medical Device Manufacturing

Discover how Liquid Silicone Rubber (LSR) injection molding machines are revolutionizing the production of medical devices. Learn about the unique properties of LSR that make it ideal for manufacturing critical components used in healthcare applications.

01/22/2024

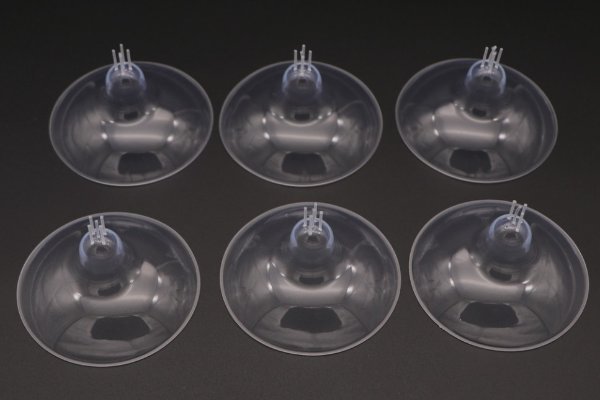

LSR baby nipple mold with cold runner by TYM- Automatic demoulding

As an expert of liquid silicone rubber injection molding machine, TYM has been engaged in the infant industry in China for many years. Over the past 16 years, we have helped our customers solve many difficult problems. Little foreign people's lactobacillus children's drinks are well known in the market, among which the disposable nipple is developed and manufactured by TYM.

The 16 cavities LSR baby nipple with cold runner is produced by 130T horizontal LSR injection molding machine. Its cycle time is about 25s which can be produced for 50,000pcs per day. There are no injection point, no flash, no second-time process, which meet the clients’ requirement for high productivity and far beyond customer expectations.

TYM has been specialized in LSR Injection molding machine for over 16 years. TYM offers LSR injection molding machine and exquisitely designed LSR baby nipple with cold runner.It is not only solves the problem of manual processing of the flying edge of the back part of the client, but also saves two workers per machine every day, greatly reducing the production cost and greatly improving the production efficiency.

TYM, as a leading enterprise of liquid silicone injection molding in China, sincerely provides customers with a complete set of solutions for equipment, molds and professional training.