Recent Posts

-

Meet TYM at K 2025 -The World’ s No.1 Trade Fair for Plastics and Rubber

Welcome to the World’s No.1 Trade Fair for Plastics and Rubber -K 2025, taking place from October 8–15, 2025 at Messe Düsseldorf, Germany. As a professional LSR injection molding machine, mold, and robot solution provider, TYM Technology Co., Ltd. is proud to present our latest innovations at Booth 16E77.

09/23/2025

-

TYM LSR Molding Solutions at Plast Eurasia Istanbul 2025

Meet TYM at Plast Eurasia 2025 to explore LSR injection molding machines, silicone and plastic molding systems, and turnkey LSR solutions. Booth: hall 805.

12/02/2025

-

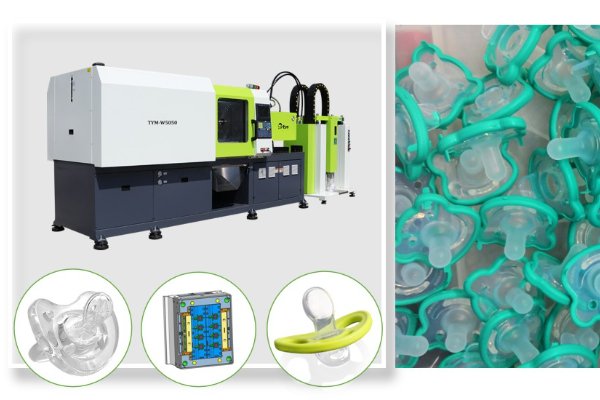

LSR Overmold Technology | Liquid Silicone Rubber Injection Molding

Liquid Silicone Rubber (LSR) overmolding has become a core manufacturing technology for producing high-precision, food-grade silicone components used in baby products, kitchenware, and consumer goods.

11/25/2025

-

Efficient Production of Silicone Phone Covers|Vertical Molding Machines

Produce premium silicone phone covers efficiently with TYM LSR vertical injection molding machines. Achieve perfect overmolding, high precision, and full automation for durable, skin-friendly silicone cases.

11/13/2025

-

Efficient LSR Half Mask Respirator Production with TYM LSR Molding Machines

What Is an LSR Half Mask Respirator? This type of respirator is made through a combination of plastic injection and LSR overmolding. First, the plastic part of the mask is molded. Then it is placed into a silicone mold for a second injection on an LSR molding machine. During this process, the liquid silicone bonds tightly with the plastic surface, forming one complete piece without any need for glue or manual assembly. This makes the mask more stable, cleaner, and easier to produce in volume.

10/09/2025

-

Liquid Silicone Half Mask Respirator Production Machine

Liquid silicone half mask respirator mold can be customized with 2 to 4 cavities and adopts a cold runner system to minimize material waste while achieving high precision molding machine.

08/14/2025

-

Silicone Catheter Manufacturing Machine LSR Molding and Extrusion

TYM provides LSR molding and extrusion solutions to manufacture silicone catheters efficiently, with modular molds and global medical-grade support.

06/25/2025

Ensuring Quality and Compliance in LSR Injection Molding

Quality assurance is paramount in Liquid Silicone Rubber (LSR) injection molding to ensure that finished products meet the stringent requirements of various industries, including medical, automotive, and consumer goods. Manufacturers rely on a combination of advanced technologies, rigorous testing protocols, and adherence to industry standards to maintain consistency and compliance in LSR molding processes.

One of the critical aspects of quality assurance in LSR injection molding is process validation, which involves verifying and documenting that the molding process consistently produces parts that meet specified requirements. This includes establishing process parameters, conducting capability studies, and performing validation runs to ensure that the process is stable and capable of meeting customer expectations.

In addition to process validation, material testing plays a crucial role in ensuring the quality and performance of LSR molded parts. Manufacturers conduct comprehensive material testing to assess the physical, mechanical, and chemical properties of silicone rubber materials, ensuring that they meet the required specifications for each application.

Furthermore, manufacturers must comply with industry regulations and standards governing LSR injection molding, particularly in highly regulated sectors such as medical device manufacturing.

This includes adhering to standards such as ISO 13485 for quality management systems in the medical device industry and ASTM D1418 for specifying silicone rubber materials.

Conclusion

Overall, quality assurance is essential in LSR injection molding to deliver products that meet customer expectations, regulatory requirements, and industry standards. By implementing robust quality control processes, conducting thorough material testing, and ensuring compliance with relevant regulations, manufacturers can achieve consistent quality and performance in LSR molding processes.

Quality assurance is a cornerstone in Liquid Silicone Rubber (LSR) injection molding, ensuring that final products meet the stringent demands of industries such as medical, automotive, and consumer goods. By integrating advanced technologies, rigorous testing protocols, and adherence to industry standards, manufacturers can maintain consistency and compliance in LSR molding processes.

Critical steps such as process validation, comprehensive material testing, and compliance with industry regulations (e.g., ISO 13485) are essential to guaranteeing product quality and performance. Through the implementation of robust quality control measures, thorough material testing, and strict regulatory compliance, manufacturers can achieve consistent quality and performance in LSR molding. This not only meets customer expectations but also ensures that products stand out in a competitive market.

FAQ

Q: Are you trading company or manufacturer?

A: We are professional manufacturer specialized in packaging machines and moulds. And we trade our products with our clients directly.

Q: Can you do OEM and ODM?

A: Yes, OEM and ODM are both acceptable. The machines and moulds can be customized as you require, the basic quantity we will advise after we discuss.

Q: Can we use our own logo?

A: Yes, we can print your private logo according to your request.